I get this question: what is the difference between sink and source when wiring the sensors to the controller? In this article, I will explain the difference between the two.

The concept of sink and source

If you have wired a sensor or transmitter to a controller such as PLC, I am sure you have heard the terms sinking and sourcing.

What are source and sink?

The concept of sink and source describes a current flow relationship between input and output devices in a control system and their power supply. The two terminologies apply only to DC (Direct Current) logic circuits.

A sinking digital I/O (input/output) provides a grounded connection to the load, whereas a sourcing digital I/O provides a voltage source to the load.

Let’s assume you want to wire a field device to a controller. If the current flows from the field device to the controller, we say that the field device is sourcing about the controller, and the controller is sinking about the field device. And vice versa is true.

One confusion I face when explaining this concept to the customer is that we can be talking about the same thing but with different references, so if someone tells you about the sink and source, always ask them what is their reference ( if it is a field device or a controller).

The most important point to remember here is that in both cases, you have current flowing from one device to another you just need to figure out in which direction.

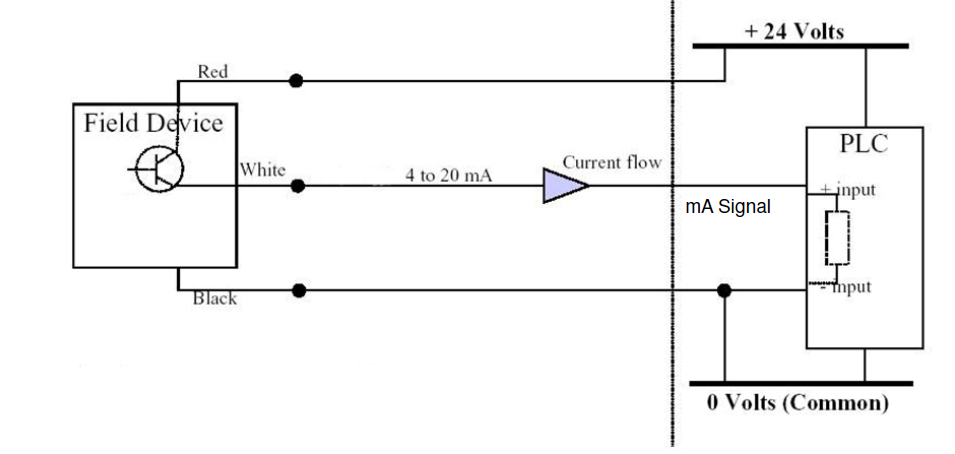

How to wire a source sensor to a controller?

The 3-wire 4-20 mA loop uses three wires to connect the field device to the controller.

Here, the signal has its wire, so you have one wire for the +, one for the -, and one for the signal.

The two wires (the + and the -) power the field device, while the signal wire carries the field device signal to the controller.

The most important thing to note is that the current moves from the field device to the controller.

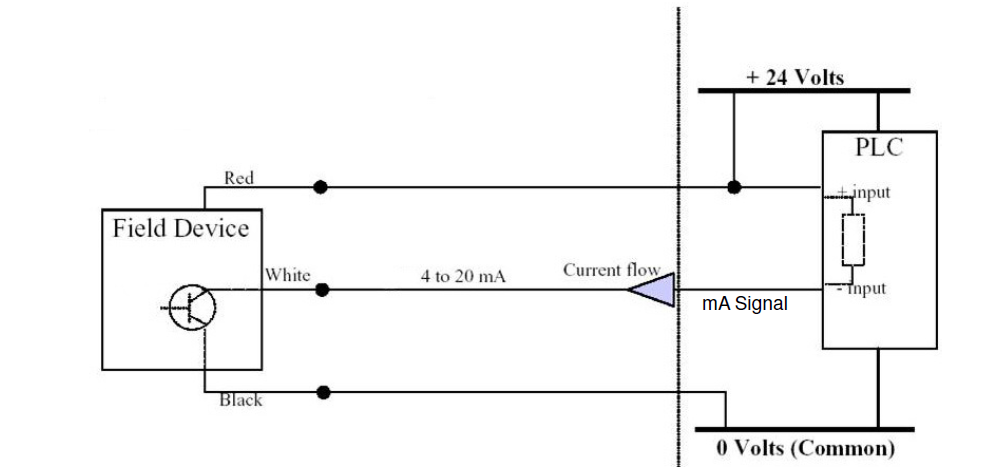

How to wire a sensor sink to a controller?

This is almost the same as the three-wire source type. The 3-wire 4-20 mA loop uses three wires to connect the field device with the controller here, the signal has its own wire, so you have one wire for the +, one for the -, and one for the signal.

The two wires (the + and the -) power the field device. In contrast, the signal wire is used to carry the field device signal to the controller, the main difference between the three wires sink and three wires source is that in the three wires sink configuration, the current signal moves from the controller to the field device.

FaQ about Sink and Source

What is the difference between sink and source?

The difference between sink and source is that in source connection the current flows from the field device to the controller, and in sink connection, the current flows from the controller to the field device.

How do I know if my controller is a sink or source?

The easiest way to know if the controller is a sink or source is to check the input card. It should specify that.

If it is unclear, you can read the controller user guide, or you can call the manufacturer, and their tech support should be able to tell you if the controller is sink or source.

How do I know if my sensor or transmitter is a sink or source?

The easiest way to know if your sensor or transmitter is a sink or source is to check the wiring diagram in the user manual or call the field device manufacturer.

In my experience, most field devices ( sensors and transmitters) come with deep switches that you can use to change them to be source, sink, or loop.

Can I wire a sink transmitter to a sink controller?

No, you can not wire a sink transmitter to a sink controller. This is because both units will be expecting to draw current from the circuit; this will read to the wrong signal being sent, and eventually, the units might not power up.

Can I wire a source transmitter to a source controller?

No, you can not wire a source transmitter to a source controller; both units will be proving current to the system, which will lead to the wrong reading, and the unit might get damaged. Do not do this.

The best way to wire is to set one unit as a sink and one as a source.

Conclusion

We have analyzed the difference between sink and source regarding wiring industrial transmitters to the controllers and also answered some frequently asked questions about the subject.

If something is unclear or you have any further questions, please leave them in the comment section below.